Eliminating the need for manual input, this intelligent machine automatically detects wheel dimensions and selects the appropriate balancing mode, weight type, and weight position. This automation accelerates the balancing cycle, reduces operational errors, and enhances efficiency.

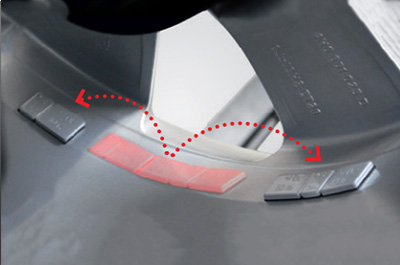

AUTOMATIC SPOKE DETECTION

A laser scanner automatically detects the number and position of rim spokes, guiding optimal weight placement behind them for precise balancing with split weights.

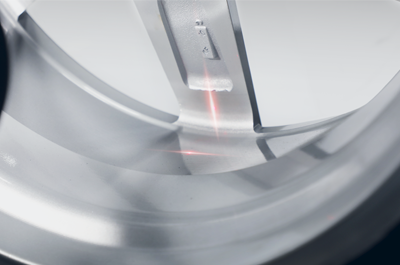

Streamlining weight placement, this precision-focused system eliminates guesswork. It employs a laser to precisely indicate the exact location for weight application, ensuring meticulous balancing and accurate results.

Optimize balancing wheels, including EV, with the latest technology and precise engineering.

The EZ-Collets mobile app helps technicians find the right collet, flange plate or speed plate for their job by selecting the vehicle. They can then compare and assess the available tools’ benefits.

Employing sophisticated techniques, this process optimizes the assembly of the tire onto the rim, reducing the need for excessive weight addition. By achieving a more balanced distribution, it enhances overall performance and minimizes potential vibrations.

Utilizing advanced electromechanical technology, this balancer incorporates a power clamping device that consistently and reliably secures the wheel with a constant force. This ensures exceptional accuracy and repeatable results every time.

Engineered for optimal performance, this feature intelligently adjusts the number of revolutions according to each wheel's specifications. Operating at maximum speed, it effectively reduces cycle time, delivering swift and efficient results.

Easily generate reports on the local network (additional hardware required) or save as PDFs on a flash drive, facilitating convenient sharing of detailed information with customers for documentation or reference.

Equipped with a powerful LED lighting system, this balancer ensures optimal illumination of the rim. This feature aids in rim cleaning and significantly assists in the precise positioning of weights, ensuring a seamless balancing process.

A vast array of measurement points are meticulously captured with an impressive resolution of 0.004″ (0.1 mm). This data is utilized to model a 3D of the tire and wheel assembly, enabling a comprehensive assessment of its uniformity. The resulting analysis determines the radial runout, presenting peak-to-peak measurements spanning from the first to the third harmonic.

Equipped with a user-friendly gauge arm, this system facilitates data entry with easyALU™ assisted rim measurement technology. Technicians simply touch the rim with the gauge arm, and the system automatically enters the rim dimensions and selects the appropriate weight-balancing mode.

This intelligent system utilizes sonar sensors to automatically detect the rim width, eliminating the need for manual input and reducing the possibility of errors. By streamlining the process, it enhances efficiency and accuracy.

This feature ensures accurate balancing and discreet weight concealment behind spokes, maintaining the wheel’s aesthetic appeal and visual presentation.

By simply touching the screen, users can prompt the system to automatically rotate the wheel to the precise position for weight application. This convenient feature streamlines the process and enhances operational efficiency.

Boasting a rapid and intuitive interface, this system incorporates a large touchscreen display with easy to read large digits. Additionally, colored weight position indicators enhance speed, ease-of-use, and overall ergonomics, facilitating daily operations.

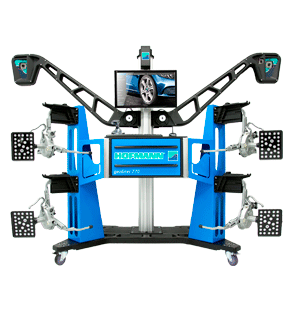

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tire Changers

Tire Changers

Lifts

Lifts