How to Choose the Best Tire Machine for Your Shop

Selecting the right tire changer can transform your auto repair shop's efficiency, profitability, and service quality. This comprehensive guide breaks down the four main types of tire changing machine and provides expert criteria for choosing the best tire machine that matches your shop's specific needs and budget.

As automotive equipment specialists with decades of experience manufacturing tire changers and wheel balancers, we understand the critical role these machines play in daily shop operations. By the end of this article, you'll have the knowledge to select a tire changer that maximizes your investment while meeting your current and future service demands.

1. Swing-Arm Tire Changer

The swing-arm tire changer represents the most affordable entry point into professional tire changing equipment, making it an attractive option for shops operating with budget constraints or lower tire volumes.

The Appeal of Entry-Level Reliability

Swing-arm tire changers excel in their simplicity and durability. These machines feature a basic but robust design that can handle standard passenger car tires reliably for years. Their affordability makes them accessible to smaller operations, independent shops, or those just starting their tire service offerings. The straightforward operation requires minimal training, allowing technicians to become proficient quickly.

The manual setup process, while more time-consuming than automated alternatives, gives operators complete control over the tire changing process. This hands-on approach can be beneficial for shops that prioritize careful handling of customer wheels or work with unique wheel designs that might challenge automated systems.

Ideal Use Cases and Limitations

Swing-arm tire changers work best for smaller shops performing 10-30 tire changes daily or operations that handle primarily standard passenger vehicle tires. They're particularly suitable for:

-

Independent garages offering basic tire services

-

Shops with budget limitations requiring reliable entry-level equipment

-

Operations where technician training time is limited

-

Businesses focusing on standard tire sizes and conventional wheel designs

However, the manual setup required for each wheel makes swing-arm models less efficient for high-throughput operations. Shops changing 50+ tires daily will find the time spent adjusting clamps and positioning becoming a significant bottleneck. Additionally, these machines typically have limited capacity for larger or specialty tires, making them unsuitable for shops serving diverse vehicle types.

2. Tilt-Back Tire Changer

The tilt-back tire changer represents a significant step up in convenience and efficiency, offering enhanced speed through its innovative tilting mechanism that simplifies adjustments between different tire sizes.

Enhanced Ease of Use and Speed

The tilt-back design allows the entire clamping mechanism to pivot, providing better access to the wheel and significantly reducing setup time between different tire sizes. This feature translates into faster changeover times compared to swing-arm models, as technicians can quickly adjust for varying wheel diameters without extensive manual reconfiguration.

The improved ergonomics reduce technician fatigue during extended tire changing sessions. The tilting mechanism brings the work closer to the operator, reducing strain and improving precision during mounting and demounting operations. Many tilt-back models also include enhanced pneumatic assist features that further streamline the tire changing process.

Positioning for Growing Operations

Tilt-back tire changer machines are ideal for mid-sized operations experiencing growth or shops employing newer technicians who benefit from more intuitive equipment operation. The enhanced efficiency makes these machines suitable for:

-

Shops handling 30-60 tire changes daily

-

Operations with a mix of experienced and newer technicians

-

Businesses expanding their tire service capabilities

-

Shops serving diverse passenger vehicle types with varying wheel sizes

The faster changeover time compared to swing-arm models can significantly impact productivity, allowing shops to serve more customers without sacrificing service quality. This efficiency gain often justifies the higher initial investment for shops experiencing steady tire service demand.

3. Touchless / Leverless Tire Changer

Touchless or leverless tire changers represent the premium tier of tire changing technology, utilizing automation and robotic assistance to eliminate operator strain while virtually eliminating the risk of wheel damage.

Premium Risk-Reducing Features

These advanced machines use sophisticated robotic arms and automated positioning systems to handle the tire changing process without direct contact between metal tools and the wheel rim. By eliminating the need for a tire spoon and manual leveraging it can dramatically reduce the possibility of scratching or damaging expensive wheels, particularly important when working with luxury vehicles or aftermarket rims.

The automation reduces physical demands on technicians, preventing repetitive strain injuries common in high-volume tire operations. Advanced models include programmable settings for different tire and wheel combinations, ensuring consistent, optimal performance across various applications.

Ideal for High-End Service Operations

Touchless tire changers excel in shops specializing in premium vehicles or performance applications where wheel protection is high-priority. They're particularly valuable for:

-

Luxury vehicle service centers

-

Shops working extensively with low profile tires

-

Operations serving performance and sports car enthusiasts

-

High-volume tire shops prioritizing efficiency and damage prevention

While the higher initial investment requires careful consideration, the protection against costly wheel damage claims and improved technician productivity often provides strong return on investment. The premium positioning also allows shops to market superior service quality, potentially justifying higher service rates.

4. Heavy-Duty Tire Changer

Heavy-duty tire changers are specialized machines designed specifically for commercial fleet service, handling the larger, heavier wheels found on trucks, buses, agricultural equipment, and other commercial vehicles.

Specialization for Commercial and Fleet Service

These robust machines feature reinforced construction, powerful hydraulic systems, and expanded capacity ranges to handle wheels weighing significantly more than passenger car applications. The hydraulic cylinder systems provide the force necessary to work with truck tires and commercial wheel assemblies that would overwhelm standard passenger car equipment.

Heavy-duty models often include additional safety features and containment systems to manage the increased forces involved in commercial tire changing. Many feature extended reach capabilities and specialized tooling designed for the unique requirements of commercial tire service.

Operational and Space Considerations

Heavy-duty tire changers require substantial floor space and often need special electrical or air compressor capacity to operate effectively. The investment extends beyond the machine cost to include:

-

Adequate shop space allocation (often 10x12 feet minimum)

-

Enhanced electrical service for larger motors

-

Upgraded air compressor capacity for pneumatic functions

-

Specialized training for technicians on safe commercial tire handling

-

Higher insurance considerations for commercial tire service

These machines are most suitable for shops with regular heavy-duty service demand, such as fleet maintenance facilities, commercial truck service centers, or full-service shops in areas with significant commercial vehicle populations. The specialized nature means they're typically not cost-effective unless commercial tire service represents a substantial portion of shop revenue.

How to Choose the Best Tire Changer

Selecting the optimal tire changer requires careful evaluation of your shop's specific needs and growth projections.

Key Selection Criteria for Shop Owners

Your daily tire volume is the primary factor in machine selection. Shops changing fewer than 20 tires daily can operate efficiently with swing-arm models, while operations exceeding 50 daily changes benefit significantly from automated features found in touchless systems.

Technician experience should be considered. Newer or less experienced technicians often perform better with more automated systems that reduce the skill requirements for consistent results. Experienced technicians may prefer the control offered by manual systems but can leverage advanced equipment for improved productivity.

The types of vehicles you regularly service is a huge factor. Shops focusing on standard passenger vehicles have different requirements than those serving luxury cars, performance vehicles, or commercial fleets. Consider your current customer base and anticipated expansion into new market segments.

Shop space availability constrains equipment options, particularly for heavy-duty applications. Measure available space carefully and consider your shop's workflow to ensure your equipment works seamlessly together.

Budget and Long-Term ROI Considerations

Initial equipment cost is just one component of total ownership expense. Consider maintenance requirements, parts availability, and service support when evaluating options. Higher-quality machines often provide better long-term value through reduced downtime and lower maintenance costs.

Labor savings potential varies significantly between machine types. Calculate potential time savings per tire change and multiply by your daily volume to understand productivity gains. Factor in reduced physical strain on technicians, which can improve job satisfaction and reduce turnover.

Damage prevention capabilities can justify premium equipment costs for shops working with expensive wheels. A single damage claim can exceed the price difference between basic and touchless equipment, making damage prevention an important financial consideration.

Future scalability should influence current equipment selection. Choosing a machine that can accommodate anticipated growth prevents premature equipment replacement as your business expands.

Conclusion

The importance of selecting the best tire machine for your shop cannot be overstated, the right equipment improves technician productivity, reduces operating costs, and enhances service quality while the wrong choice can create bottlenecks, increase labor costs, and limit growth potential.

Ready to explore tire changers that match your shop's specific needs? Browse our complete line of tire changers to find the perfect equipment solution for your operation. Our experienced team can help you evaluate your requirements and select the optimal tire changing machine for your shop's success.

Key Features to Look for in a Tire Changer for High-Volume Shops

How to Choose the Right Tire Balancing Machine for Your Shop

How Alignment Services Increase Customer Retention for Tire Shops

The ROI of 3D Wheel Alignment Systems

Hands-On Innovation: How EZ-Toe™ Simplifies Toe Adjustments

Wheel Alignment: A Complete Guide

Symmetric vs Asymmetric Lift: The Key Differences Every Shop Should Know

How to Use a Tire Machine: A Step-by-Step Guide for Safe Operation

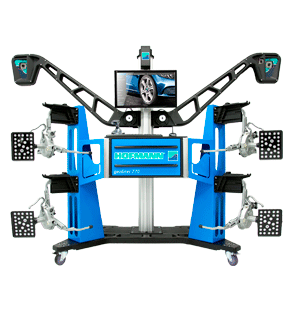

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tire Changers

Tire Changers

Lifts

Lifts