How to Balance Tires: The Complete Guide

Balancing tires might not always be at the top of your mind, but it’s an essential part of vehicle maintenance. Your tires are the sole contact point between your car and the road and by ensuring proper balance, you can enhance your vehicle’s safety, optimize its performance, and extend the lifespan of your tires.

When tires are unbalanced, the consequences can escalate quickly. From uneven tire tread wear to vibrations that affect your comfort behind the wheel, imbalances can strain your vehicle and lead to more significant issues over time. If left unchecked, these problems can compromise your safety and result in costly repairs.

This guide explores the ins and outs of tire balancing, including its importance, the signs that indicate your tires need attention, and how professionals tackle the process. Whether you’re here to solve a specific problem or simply broaden your understanding, this article covers everything you need to know about maintaining proper tire balance.

Why is Tire Balancing Important?

Balanced tires are the key to a safer, smoother and more cost effective driving experience. When a tire and wheel assembly is out of balance, it creates vibrations that can disrupt stability and affect how your vehicle handles on the road. Beyond just a rough ride, these imbalances can have far reaching impacts on your tires and other critical components.

One major consequence of unbalanced tires is uneven tread wear. Certain areas of the tire are subjected to more pressure, causing them to wear down faster in certain tread sections. This is called cupping. These patterns reduce their ability to maintain proper traction, which is especially concerning in wet or slippery conditions. While some tread wear is expected over the lifespan of a tire, these irregular patterns point to an underlying balance, or more often wheel alignment problem that requires immediate attention. Gross imbalance can cause unnecessary wear on key components like suspension and steering parts.

Comfort is another important factor to consider. Vibrations caused by imbalanced tires signal problems that can snowball into more serious mechanical issues if ignored. Properly balanced tires eliminate these vibrations, resulting in a quieter, smoother ride.

By investing in regular tire balancing, you protect your tires from premature wear and reduce stress on vital parts of your vehicle. This not only enhances performance but also helps you avoid unexpected repairs and ensures your vehicle stays roadworthy for longer.

How to Tell if Your Tires Need Balancing

Recognizing the early warning signs of tire imbalance can save you from bigger headaches down the road. One of the first symptoms many drivers notice is vibration. This can often be felt through the steering wheel, floor, or seats. Vibrations caused by tire imbalance tend to become more pronounced at higher speeds, making long drives particularly uncomfortable.

Unusual noises are also worth noting. Sounds like humming or rhythmic thumping are often caused by the uneven distribution of weight within the tire and wheel assembly. Ignoring these noises can exacerbate wear and lead to further strain on your vehicle’s components.

To keep your tires in top condition, it’s crucial to balance them regularly. Tires should be balanced whenever they’re installed, rotated, or repaired. For most vehicles, it’s a good idea to schedule balancing checks every 5,000 to 6,000 miles, typically aligning with routine tire rotations. Staying proactive helps prevent wear and tear while ensuring a safer and more comfortable ride.

How Tire Balancers Measure Imbalance: Step-by-Step

Tire balancing is not just about adding weights; it’s about creating harmony between the tire and wheel to ensure smooth driving, reduced wear, and better fuel efficiency. Achieving a perfectly balanced tire and wheel assembly requires careful attention to each step.

Here’s a breakdown of the step-by-step process:

-

Mounting the Wheel: The first step in tire balancing is securely attaching the wheel to the balancer. Technicians use specialized clamps or adaptors to ensure that the wheel is properly centered. Any misalignment during this process can lead to inaccurate readings, potentially throwing off the entire balance.

-

Spinning the Wheel: Once mounted, the wheel is rotated at a controlled speed. This rotation allows the balancer to detect inconsistencies in weight distribution that might disrupt the wheel's stability. Accurate rotation is critical for identifying where adjustments are needed.

-

Measuring Imbalance: Sophisticated sensors within the machine analyze the wheel’s movement, pinpointing areas of uneven weight. The measurements help identify both the magnitude of the imbalance and its exact location, giving technicians the data they need to correct the issue accurately.

-

Identifying Correction Points: Using the collected data, the balancer pinpoints the areas where weights should be applied to restore balance. These specific locations are marked for the technician, ensuring that the corrections are precise and effective.

-

Applying Wheel Weights: Technicians carefully attach adhesive or clip-on weights to the designated areas. These weights are used to counteract the imbalances detected earlier, helping the wheel achieve smooth and even rotation. Precision is key here to avoid the need for repeated adjustments.

-

Rechecking Balance: After the weights are applied, the wheel is spun again to confirm the corrections. If any residual imbalance remains, additional fine-tuning is performed to achieve optimal balance.

Advancements in Tire Balancing Technology

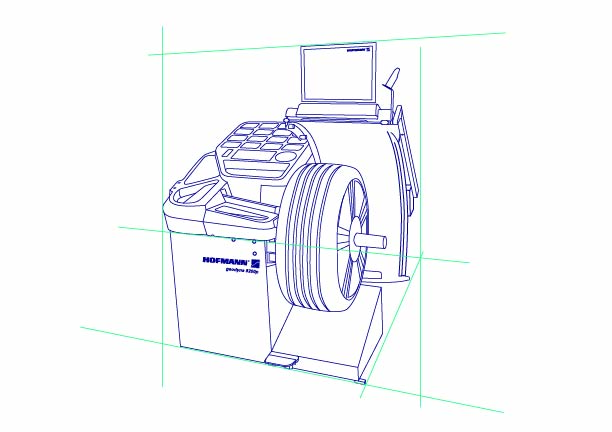

Tire balancing has come a long way, with modern equipment transforming what was once a tedious process into something faster, more precise, and remarkably efficient. Today’s machines are designed to simplify the work for technicians while delivering consistent, accurate results, and the Hofmann® geodyna® 8200 is a standout example of this innovation.

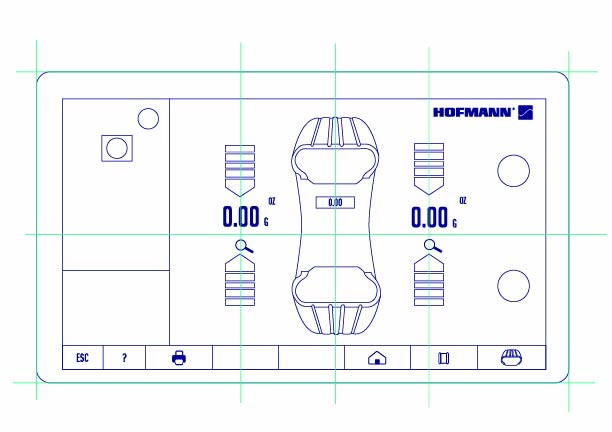

The first priority for advanced tire balancers is ensuring ease of operation. The geodyna® 8200 touchscreen interface offers a user-friendly experience that helps technicians navigate settings and tasks with minimal effort. It can also gather wheel dimensions automatically. By removing the need for manual data entry, this system ensures both speed and accuracy, giving technicians the ability to complete more work per day.

Hofmann smartSonar technology measures rim width with precision, eliminating common errors and making the process smoother. Combined with features like laser-guided wheel weight placement, which pinpoints the exact spots for weights, and the secure power clamping system, this machine guarantees consistent, professional results.

Innovations like these don’t just benefit the workshop, they directly enhance the driving experience. With better tools, technicians can balance tires more effectively, leading to longer-lasting tires, improved ride quality, and safer journeys on the road.

Conclusion

Tire balancing is an indispensable part of vehicle maintenance that enhances safety, performance, and overall comfort. When tires and wheels are balanced correctly, drivers enjoy a smoother ride, better fuel economy, and extended tire life. Ignoring this critical service however can lead to vibrations, uneven tread wear, and costly repairs.

A tire shop that invests in high quality wheel balancing technology can improve the accuracy and speed of their repair work, leading to happier customers and more jobs completed. Explore our line of innovative wheel balancers today and ensure your business delivers the best tire service possible.

Key Features to Look for in a Tire Changer for High-Volume Shops

How to Choose the Right Tire Balancing Machine for Your Shop

How Alignment Services Increase Customer Retention for Tire Shops

The ROI of 3D Wheel Alignment Systems

Hands-On Innovation: How EZ-Toe™ Simplifies Toe Adjustments

Wheel Alignment: A Complete Guide

How to Choose the Best Tire Machine for Your Shop

Symmetric vs Asymmetric Lift: The Key Differences Every Shop Should Know

How to Use a Tire Machine: A Step-by-Step Guide for Safe Operation

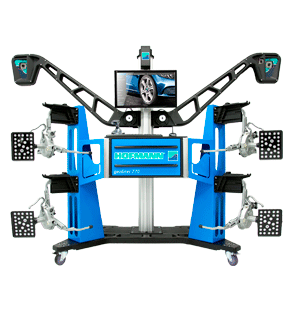

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tire Changers

Tire Changers

Lifts

Lifts