How to Choose the Right Tire Balancing Machine for Your Shop

Choosing the right tire balancer is an important investment that affects your shop's efficiency, service quality, and long-term profitability. With so many options available, each with different features, space requirements, and price points, you need to assess your specific needs before buying.

This guide walks you through the key factors to consider, from machine types and features to support and certification, so you can make a confident, informed decision.

Assess Your Shop's Needs

Determine the Types of Vehicles You Service

Consider the tire and wheel sizes you handle most frequently, along with their weights and performance requirements. Your balancing equipment must support your most common applications, whether you primarily service passenger vehicles, light trucks, or heavy-duty commercial vehicles.

Evaluate Your Balancing Volume

High-volume shops benefit from faster, automated balancers that minimize operator error and reduce turnaround time. Lower-volume shops might prioritize versatility over speed, choosing equipment that handles various wheel types well.

Set a Realistic Budget

Factor in purchase cost, installation expenses, and ongoing maintenance requirements. Calculate your potential return on investment from faster service times and reduced customer comebacks. Quality equipment typically offers better long-term value than budget options.

Measure Your Shop's Floor Space

Check machine dimensions and ensure adequate room for technicians to handle wheels safely and efficiently. Your wheel balancing service area should integrate smoothly with your shop's workflow.

Look at Software and System Integration

Choose balancers with intuitive user interfaces and step-by-step procedures that reduce training time. Models that integrate with your shop management system streamline operations by automatically logging services and tracking productivity.

Research Service and Training Support

Select manufacturers with strong reputations for customer support. Verify that local service technicians can provide prompt maintenance and repairs when needed. Post-sale support matters as much as the initial purchase.

Understand the Types of Tire Balancers

Static Balancers

Basic and affordable options that balance wheels in a single plane. These work well for low-volume shops or specialty applications, particularly vintage vehicles or situations where simple balancing suffices.

Dynamic Balancers

The standard for modern tire shops, these machines balance wheels across multiple planes. Dynamic balancing eliminates both static and couple imbalances, ensuring smooth operation at highway speeds. Most shops choose dynamic balancers as their primary equipment.

Heavy-Duty Balancers

Designed for trucks, buses, and commercial vehicles, these robust machines handle high-weight assemblies that would overwhelm standard equipment. They feature reinforced components, larger shaft sizes, and specialized adapters for commercial wheel configurations.

Key Features to Look For

-

Accuracy and Repeatability: Your equipment must deliver consistent, accurate results to reduce vibration and eliminate customer comebacks. Even small imbalances cause noticeable vibrations at highway speeds.

-

Speed and Workflow Efficiency: Seek balancers with automatic data entry features that measure rim width, diameter, and offset without manual input. Laser-guided weight placement systems speed up the balancing process while improving accuracy. Touchless measurement features protect expensive wheels from damage.

-

Durability and Reliability: Your tire balancing machine must withstand heavy daily use. Evaluate build quality, component materials, and engineering design. Reliable equipment minimizes downtime and reduces repair costs.

-

Advanced Diagnostic Tools: Features like road force measurement identify tire and wheel issues that standard balancing cannot detect. Runout detection and rim condition analysis help diagnose vibration problems from bent wheels or tire defects.

-

Ease of Use and Training: Choose machines with intuitive displays, clear visual guides, and step-by-step prompts. User-friendly interfaces reduce balancing errors that lead to comebacks.

Evaluate Manufacturer Reputation and Support

Industry Certifications: Verify that equipment meets relevant safety and performance standards. Certifications provide confidence that your investment meets professional standards for accuracy and safety.

Warranty and Service Plans: Choose vendors offering comprehensive warranties and accessible service support. Ensure calibration services, replacement parts, and technical support remain available throughout the equipment's service life.

Customer Reviews and Testimonials: Research experiences from shops with similar workloads and vehicle types. Online reviews and industry forums provide valuable insights into real-world performance and reliability.

Conclusion: Match Machine Capabilities with Shop Goals

Selecting the best tire balancing machine requires careful evaluation of your shop's size, volume, and service mix. The right wheel balancer improves efficiency, ensures accuracy, and enhances customer satisfaction.

Request live demonstrations to see machines in action. Consult with manufacturer representatives who can recommend configurations suited to your shop's unique needs. Your tire and wheel balancing equipment represents a long-term investment in your shop's success. Quality wheel balancers pay for themselves through improved productivity, reduced comebacks, and enhanced customer loyalty.

View our wheel balancer selection to explore professional-grade tire balancing machines designed for shops that demand precision, efficiency, and reliability.

Key Features to Look for in a Tire Changer for High-Volume Shops

How Alignment Services Increase Customer Retention for Tire Shops

The ROI of 3D Wheel Alignment Systems

Hands-On Innovation: How EZ-Toe™ Simplifies Toe Adjustments

Wheel Alignment: A Complete Guide

How to Choose the Best Tire Machine for Your Shop

Symmetric vs Asymmetric Lift: The Key Differences Every Shop Should Know

How to Use a Tire Machine: A Step-by-Step Guide for Safe Operation

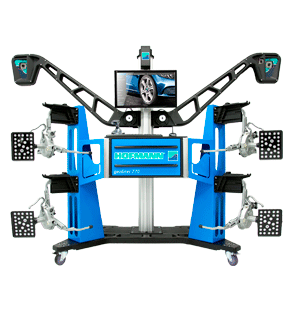

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tire Changers

Tire Changers

Lifts

Lifts