Home / Equipment / Testing / Joint Play Detectors / WEARTEST 2300 FA

WEARTEST 2300 FA

JOINT PLAY DETECTOR FOR CARS

WEARTEST 2300 FA:

Precision Joint Play Detection for Vehicles up to 4 Tons Axle Load

The WEARTEST 2300 FA from Hofmann is a specialised joint play detector designed for both cars and trucks with axle loads of up to 4 tons. It features hydraulically operated test plates that can move in both counter and same directions, enabling comprehensive checks of axle suspension, axle stub, wheel bearings, tie-rod ends, and stabilisers. This equipment operates on a standard power supply of 400 VAC at 50 Hz and offers a choice of test modes via a radio-controlled test lamp, with easy single-touch operation and the option for both automatic and manual modes. It offers a reliable solution for assessing joint play in vehicles, enhancing the precision and safety of post-collision repairs.

FEATURES

Hydraulic Test Plates:

These hydraulic test plates offer the versatility of dual-direction movement, allowing precise assessments. They seamlessly return to their home position automatically, ensuring efficiency and convenience.

Comprehensive Evaluations:

Conduct thorough and meticulous inspections encompassing axle suspension, axle stub, wheel bearing, tie-rod ends, and stabiliser components, ensuring a comprehensive assessment of the vehicle's suspension.

Versatile Testing Modes:

Choose from a wide array of testing modes, accessible via a test lamp, simplifying the operational process and accommodating various testing requirements.

Operational Flexibility:

Opt for either an automatic or manual mode of operation, adapting the system to specific testing needs with ease and convenience.

Remote Control Capabilities:

The system includes essential components such as a hydraulic unit, a control cabinet, and a test lamp featuring 18 long-life LEDs, making it adaptable for effective remote control.

Durable Keypad:

The keypad for this system is thoughtfully designed with oil- and petro-resistant foil, ensuring long-lasting durability in various operational conditions.

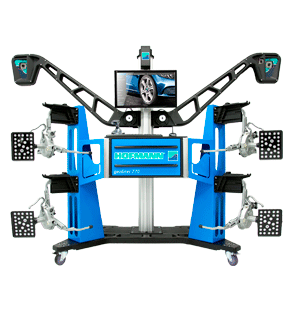

Wheel Aligners

Wheel Aligners

Wheel Balancers

Wheel Balancers

Tyre Changers

Tyre Changers

Lifts

Lifts

Testing

Testing